At 193kg, Lamborghini’s new DCT weighs notably less than the Huracán’s seven-speeder

How lamborghini’s lightweight, pre-selecting transmission forms part of its new flagship’s hybrid system

Since they hit the mainstream in the early 2000s, dual-clutch transmissions (DCTs) have travelled a long a curious curve of driver acceptance.

Initial joy that they were so much more compelling than the torque-converter slushers and automated manuals they replaced eventually gave way to a yearning for manuals as the novelty wore off.

However, it’s hard to imagine Lamborghini’s new LB744 plug-in hybrid hypercar being fitted with anything else.

Developed at Sant’Agata but doubtless drawing on the wider Volkswagen Group’s huge experience with DCT technology, Lamborghini’s eight-speed “double-clutch” transmission (so many different names for the same thing) is completely new and developed especially for the LB744.

Breaking with Lamborghini’s tradition of mainly longitudinal engines and forward-facing gearboxes, the LB744 is powered by what might be described as a T-drive, with a longitudinal engine coupled to a transverse gearbox behind it. What would’ve been the transmission tunnel ahead of the battery is occupied by a small (3.8kWh) drive battery.

All DCTs work on the principle of splitting gear ratios between separate shafts within the gearbox. Longitudinal gearboxes might have two shafts, whereas those designed to fit in the compact spaces of front-wheel-drive cars, like Volkswagen’s DSG ’boxes, might have three. Despite the transverse mounting of Lamborghini’s unit, the design is able to stick to two, no doubt because of the car’s width.

The gears are arranged with the even numbers on one shaft and odd numbers on the other, each set being controlled by one clutch. As with all DCTs, the idea is that when the car is accelerating through upshifts, the gearbox preselects the next ratio but the clutch controlling it remains open.

When the driver calls for a shift, the clutches simultaneously opens and closes, taking the previous ratio out of drive while introducing the higher ratio at exactly the same time. In this case, a feature called continuous downshifting (activated if you hold down the left paddle) drops the DCT through multiple gears under braking to give you a greater sense of control.

At 193kg, Lamborghini’s new eight-speed DCT weighs notably less than the Huracán’s seven-speeder. It’s faster-shifting, too.

The gearbox’s role as part of a drive system is more complete than usual in that it forms part of the hybrid strategy. Of the LB744’s three electric drive motors, one is located above the gearbox while the other two are axial flux (pancake-style), one on each wheel.

The rear motor also acts as the starter and in generator mode powers the front motors via the battery. An uncoupling mechanism with a dedicated synchroniser connects the motor to the gearbox, allowing it to be connected to the engine or independently to the wheels. In that way, it can either feed power to the engine or be driven by the engine to generate electricity. When it’s uncoupled from the engine and driving the wheels alone, the LB744 becomes a 4WD EV.

Another clever touch is the use of the front motors for reversing, removing the need for a reverse gear in the gearbox and thereby helping weight reduction.

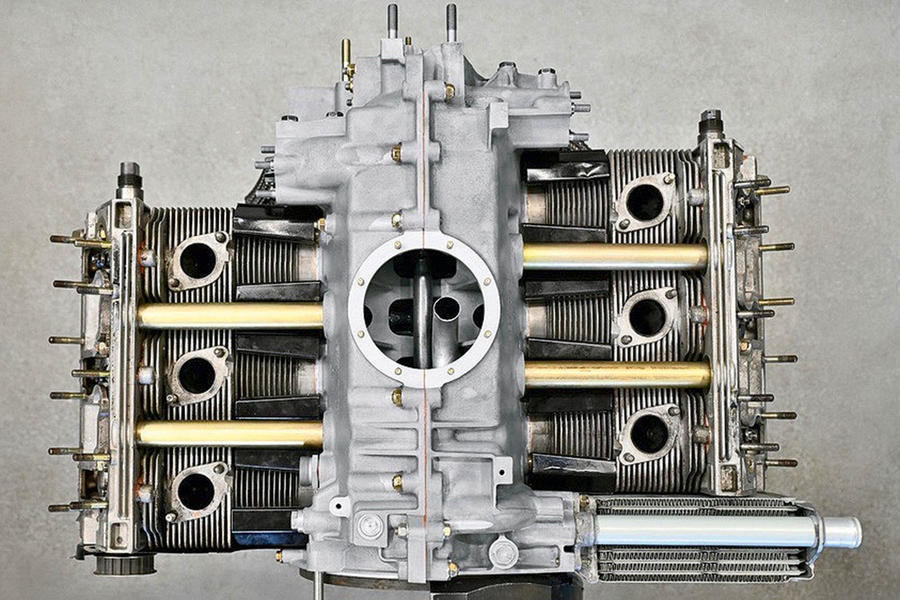

Porsche’s new crankcases for 60s and 70s 911s

Porsche has begun producing engine crankcases for older 1960s and 1970s Porsche 911s again but using the latest production techniques. Starting with computer-aided design data, moulds are made from sand bonded with a resin. Once freed from the moulds, the castings are machined by five-axis computer numerical control machines and checked for accuracy using 3D-measuring probes.

Source: Autocar