Nissan is converting Sunderland into its key EV production hub

Factory will build next-generation Qashqai and Juke alongside new Leaf following £2 billion investment

Making Sunderland pay as a production location will be key to Nissan’s shift to sustainable profitability in the coming years – a job that’s about to become a lot harder as it moves to building electric cars only.

Sunderland in the north-east of England churns out more cars annually than any other plant in the UK, a position it has held for over a decade.

The 362,000-square-metre site – equivalent to 50 football pitches – holds the key to Nissan’s profitability in Europe, making as it does the brand’s top-sellers in the form of the Nissan Qashqai compact SUV and Nissan Juke small SUV. It’s also the brand’s only European factory after it shut its Barcelona facility in 2021.

Strong sales for hybrid versions of the Qashqai and Juke in 2023 helped tip Nissan back into profit in Europe in the six months to the end of November, according to its own figures, giving hope that the brand has turned a corner following a string of losses going back to 2012.

But now Nissan has the headache of making Sunderland build electric cars only. All subsequent models leaving the factory will be battery-powered, starting with the new Nissan Leaf compact crossover scheduled to be launched in late 2024, with the replacement for the Juke following that, potentially in 2026, and then after that the Qashqai. Nissan plans to only be selling EVs in Europe from 2030.

“All the passenger car investment from now on is mainly concerned with EV,” Nissan CEO Makoto Uchida told journalists at the announcement in November of further investment in Sunderland to shift to an all-EV facility.

And that’s hard work. “The profitability of electrification and electric vehicles has not reached a satisfactory level,” said Uchida on the company’s most recent earnings call.

Nissan has, of course, been making the Leaf EV at Sunderland since 2013, but the car has been a rolling reminder of the difficulty of building electric vehicles profitably. When the car was originally built, the 24kWh pack cost around $8000 to $9000 (about £6300-£7100), equating to around $330-$375 (£260-£300) per kilowatt hour, according to former Renault and Nissan executive Patrick Pelata, who took over product planning at Nissan in 1999.

Pack prices have since dropped by around two-thirds, but given the low volumes of both batteries and cars, the second-generation Leaf is unlikely to be a significant profit generator for the company.

The third-generation Leaf will add the volume needed, predicted by Nissan to be around 100,000 units a year, as well as increasing the density and therefore range in the fifth-generation battery made on site by battery partner Envision AESC in a new facility under construction.

The aim is to build the Leaf as well as the Juke and Qashqai EVs to sell at a price on a par with equivalent combustion-engine models. Uchida acknowledges the difficulty. “How we achieve parity with ICE is a challenging discussion,” he said at the Sunderland announcement.

The scale is going in at a battery level but Nissan warns that it needs to extend to other suppliers as well. Britain’s remaining car makers have long complained that our comparatively low output compared with other European car-making countries means we’re not attractive enough to suppliers when they look to build new regional production hubs.

One problem has been the lack of time to prepare. “The speed of electrification came earlier than we thought,” said Uchida.

There are other levers to pull. Uchida pointed to the fact that Nissan has traditionally had a lot of diversity and complexity in its model line-up, and hinted at simpler specs in the future. He also warned that more driver actions would shift to the touchscreen. “It is moving much faster from that perspective,” he said.

Helping the reduction in complexity is the fact that all three new electric models will be built on the same CMF-EV platform that currently underpins the Japanese-built Nissan Ariya EV, as well as the Renault Mégane E-Tech.

In fact, Sunderland will actively discourage any model that doesn’t share a high degree of common parts. “It’s exactly why we weren’t interested in producing the next Micra here,” said Alan Johnson, head of manufacturing and supply chain management for Nissan in Europe. “Because if we start getting oddballs it makes the whole thing more complicated.” The new electric Micra will be built in France alongside the related Renault 5 to better make the economies of scale work.

Nissan Sunderland has had its fair share of ‘oddballs’ in the past, most recently the ill-fated Infiniti Q30 and QX30 premium compact pair, which were shoehorned into Sunderland from 2016 despite being based on a Mercedes platform. The cars were axed in 2019 following poor sales.

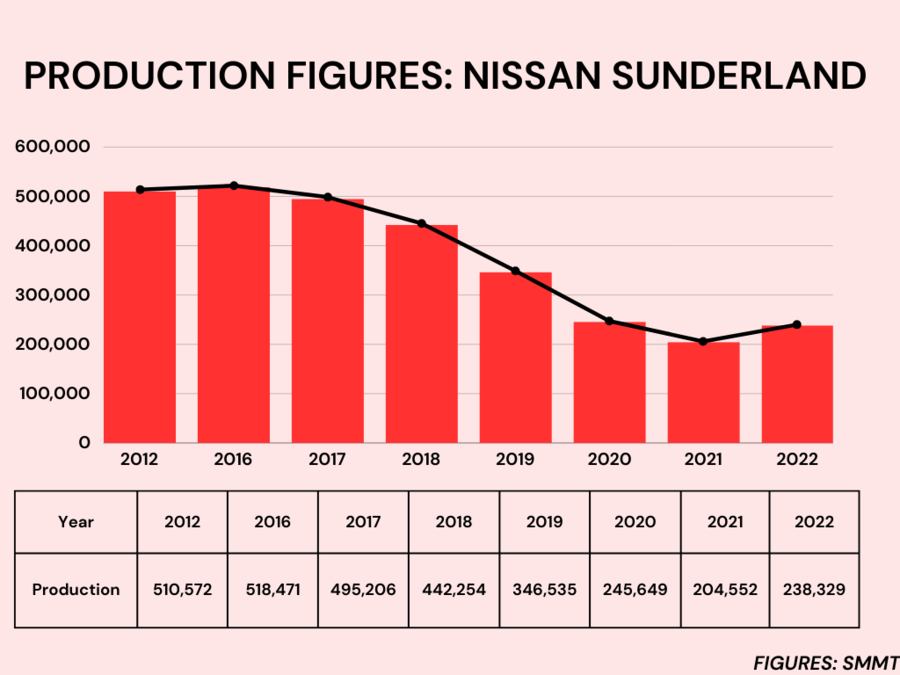

Nissan Sunderland is a long way from its heyday in 2012-2017 when it was producing over half a million cars a year. Last year the factory built 238,329 cars, according to figures from industry body the SMMT. Production is increasing again but Johnson is wary of going back to the half-million days and is instead aiming for the “sweet spot” of 400,000-450,000 a year.

That’s maximum capacity at two shifts a day, which is a lot easier to manage than the three shifts of old. The employee levels reflect that at around 6000 now compared with 7000 in the heyday. “The cost of running three shifts are significant higher,” said Johnson. More volume is nice but he wants to avoid a situation in which it’s only viable for a certain period. “You don’t want to mess people about,” he said.

The problem is that planning volumes is so much more difficult. “The real big question with our new product is how successful are they going to be? I’ve learned over the years, it’s extremely difficult to predict,” said Johnson. “Sometimes you’re too optimistic. Sometimes too pessimistic. Very rarely do you get it right.”

It’s even harder as the world stumbles from one geopolitical shock to the next. “The trick is to be sufficiently cautious that from a business planning point of view you know you’re protected and that you have some margins in there,” said Johnson.

With all three EVs sharing parts to a greater degree than, say, the Qashqai e-Power and the Juke Hybrid, then the unexpected success of one model can offset any potential disappointment generated by another.

Johnson is reluctant to make both production lines at Sunderland flexible enough to make all three cars, however. “That flexibility comes with a price tag,” he said. “I’d love to have more flexibility [but I’m] not sure we can justify it.”

Given, however, the high proportion of the battery cost in the bill of materials for any new EV, much will depend on whether AESC can make the batteries cheap enough, especially with the high demands of electricity from a cell plant. Right now in the UK, energy pricing is a significant factor. “Energy has gone from being not quite negligible but small to becoming a much bigger proportion of the overall cost,” said Johnson.

Uchida has also hinted at potentially switching to lower-cost lithium-iron-phosphate (LFP) batteries from the pricier but denser lithium ion cells using cobalt.

All car makers in the UK will eventually build EVs. However, with Toyota yet to commit, Nissan is the only one here making the shift without premium pricing to cushion the potential hit on margins that moving to electric will inevitably bring. The pressure is on to make it work.

Source: Autocar